The Car Clutch System: Understanding How It Works

Just imagine you’re cruising down a scenic, winding road in Waltham, MA. The wind rushes through your hair, the engine hums smoothly underneath you, and suddenly, there’s an unexpected stutter in your car’s movement. Could it be a problem with the drive shaft or, perhaps more distressingly, a troubled clutch system?

The clutch controls your vehicle’s transmission in the same way that the heart does for our bodies. We will delve into the complexities and intricacies of clutch systems in this blog. We will go over how a properly maintained clutch can unlock your car’s full potential, keeping it purring smoothly down those lovely winding roads for miles and miles to come.

Buckle up and learn more about your vehicle’s unsung hero, the clutch. It could end up saving you from upsetting future vehicle malfunctions and towering repair bills!

Basics of Car Clutch Systems

A clutch, quite crucially, is an essential component of your car that allows the engine to be disengaged from the wheels when you shift gears, preventing your engine from stalling when you come to a halt. A common clutch system mainly comprises three essential parts: the flywheel, the clutch plate, and the pressure plate.

When you press your foot on the clutch pedal, the connecting rod pushes against a release fork, which in turn presses down on a pressure plate and releases it from the clutch plate. The connecting rod in the system’s shaft facilitates this motion, which disengages the engine from the transmission.

Consider a bicycle with gears to help you better understand how a clutch operates. Your bike’s gears are changed by altering the resistance of your pedal stroke, which moves the chain between two sprockets of varying sizes.

Similar to changing gears on a bicycle, changing the ratio between two spinning components in a car is necessary to change the gear speed.

The utility of clutches is not limited to manual vehicles;: they are found in both manual and automatic transmissions. In automatic transmission systems, however, there is no need for a driver to operate a clutch pedal while driving because they only have two pedals – the brake and accelerator pedals.

One key advantage of a manual clutch system over an automatic is that it allows drivers to operate their cars more efficiently. Manual transmissions bestow drivers with more control over their vehicles, as they can decide at what moment and how swiftly they want to change gears. This degree of control can yield better fuel economy when harnessed correctly.

Yet, the silver lining of fuel economy in manual systems does not overshadow the challenge it presents, especially for inexperienced drivers. Even proficient drivers may occasionally find themselves committing gear change errors, leading to misshifts and consequential damage to both their vehicles and wallets.

Now that we’ve covered some basics about clutches, we are ready to delve further into the nitty-gritty details, evaluating the differences between manual and automatic clutches.

Manual vs Automatic Clutches

The main distinction between manual and automatic clutches is how they engage and disengage the engine and transmission. Manual transmissions require drivers to operate a third pedal to disengage the flywheel and brake before shifting gears. Conversely, automatic transmissions utilize a fluid coupling or torque converter instead of a clutch.

To illustrate this difference, imagine two friends racing each other on a track; one is behind the wheel of an automatic while the other test drives a manual. The driver with the manual car needs to work his clutch to shift gears while racing, taking some time between gear changes but benefiting from a higher level of control over their vehicle.

Conversely, the driver with an automatic uses drive-by-wire hardware, a modern type of linkage system, instead to change between gears faster at the cost of less precise control over their car. In this system, electronic signals replace the traditional mechanical input shaft, resulting in a different type of vehicle operation.

Car enthusiasts favor manual transmissions as one of the various transmission system types because of the enhanced sense of control they offer in high-performance situations like racing or off-road excursions.

On the other hand, most regular drivers prefer automatic transmissions due to the comfort and convenience they offer in heavy traffic conditions, allowing easier multitasking.

However, automatic transmissions may not have the same reliability as manual transmissions. They can often get confused about what gear to choose for certain driving situations, like uphill inclines, leading to unnecessary strain on your engine or lower fuel economy. Think of it as having your phone setup do things for you automatically even if you didn’t intend it vs. having full control over the applications you’re using so that specific actions get achieved efficiently.

When buying a new vehicle, whether it is automated or has a manual option, being aware of this information will be helpful. Next, we will discuss the input shaft and linkage facilities of car clutch systems.

- A research study conducted in 2020 showed that approximately 70% of manual cars suffer from clutch issues due to user mishandling.

- The American Automobile Association reported in 2022 that well-maintained and gently used car clutches can last for more than 100,000 miles, proving to be higher than the earlier thought estimation of approximately 80,000 miles.

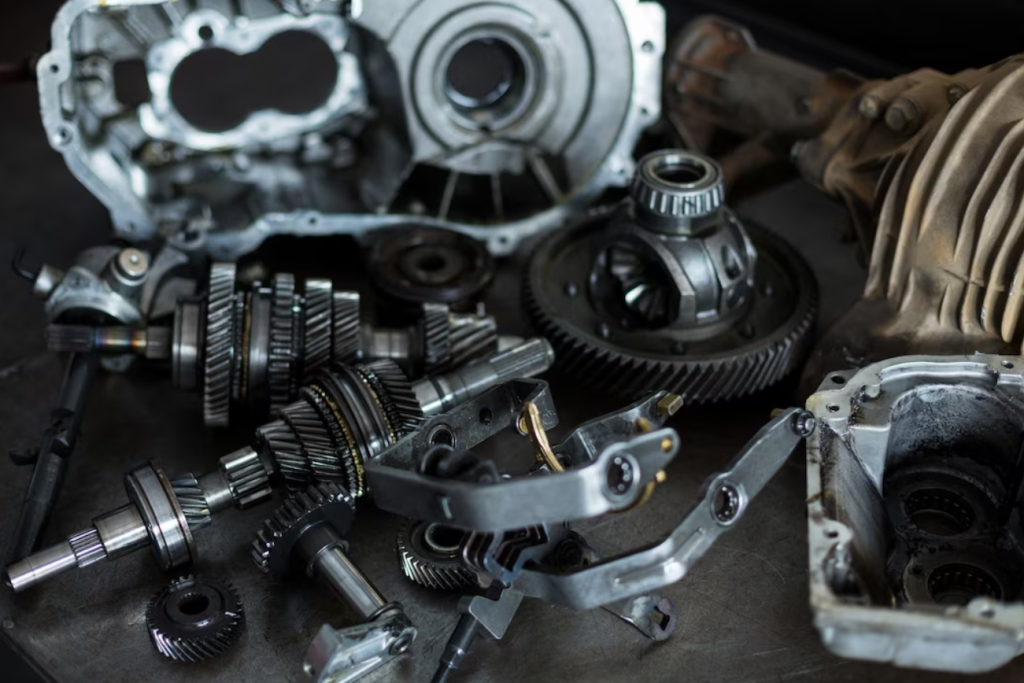

Key Components of a Car Clutch System

The clutch system of a car is composed of several key components that work together to facilitate the transfer of power from the engine to the wheels. Among these are several types of parts, including the input shaft, which transmits engine rotation into the gearbox, and the linkage, a connection facilitating gear shifting.

As we have discussed earlier, the primary function of the clutch is to engage and disengage the transmission from the engine. This allows for smooth gear changes and control over the vehicle’s movement.

Let us now discuss in detail some of the key components that make up a car’s clutch system.

Firstly, there is the clutch disc. It is one of the most crucial parts of the clutch system. The clutch disc is sandwiched between two plates—the flywheel and pressure plate—and it rotates with the engine flywheel when engaged. When you press down on the clutch pedal, it causes a release mechanism to disengage these plates, which allows for smooth gear changes.

Another important component is the flywheel itself. The flywheel is fixed to the engine crankshaft, directly linked to the input shaft, and serves as a coupling point for the engine and clutch assembly. It also provides inertia for smoother operation when changing gears. Think of it like a spinning gyroscope: because of its rotation, it resists changes in speed or direction and helps stabilize shifting.

Finally, there is the pressure plate, which uses springs to clamp down on and release the clutch disc. By engaging or disengaging frictional contact, these springs regulate the amount of torque that can be transferred between the engine and transmission. The connection between these components ensures a smooth transfer of power.

For instance, imagine you’re driving uphill in third gear at low RPMs. You will likely experience engine lug, where your engine feels like it is chugging due to inadequate torque output.

Under normal circumstances, pressing down on your clutch pedal will take all of this resistance away and allow higher RPMs for more torque output if you were driving at higher speeds in fourth gear instead (say, on level ground). The spring pressure in the clutch kit helps determine how quickly this transition can take place. In terms of durability, each component of a car must endure a lot of friction and potential slippage over its lifespan.

The clutch disc, for example, with its various cylinders, may wear down due to heat or debris from a failed flywheel or pressure plate surface. This wear and tear could even affect coil springs, which are integral to the suspension system. The same can happen with the flywheel’s reduced thickness or uneven surfaces, which impede proper operation and cause extra wear on other components.

Opinions differ when it comes to replacing individual parts versus purchasing a new clutch kit. While some may argue that replacing specific parts, such as a failed set of coil springs or cylinders, is less expensive than purchasing a new clutch kit, others may argue that using an aftermarket replacement may jeopardize the overall system’s safety and reliability.

As a result, slippage may become a concern. Finally, the driver’s desired level of vehicle performance, as well as the mechanic’s training and experience, determine this choice. With an understanding of these key components, let us now look at how one specific item, the flywheel, plays an important role in the operation of a car clutch system.

The flywheel, with its integrated cylinders, is one of the most critical elements responsible for facilitating smooth engagements and disengagements between engine and transmission through its rotational inertia.

But what exactly does it do?

The Role of the Flywheel

Firstly, it acts as a true mounting point for the clutch assembly (disc, pressure plate, and coil springs) while also connecting directly to the engine crankshaft via bolts. When engaged, the flywheel is typically machined flat and even on both sides to ensure consistent contact with the clutch plates, which are sandwiched together between two flat surfaces.

Secondly, and perhaps most importantly from an operational perspective, is its ability to store rotational energy. This occurs as energy input from engine combustion is converted into turning motion and stored in this spinning mass.

When shifting gears manually or briefly entering neutral mode, this stored energy can smooth out the transition against any slowing or accelerating forces encountered prior to clutch reengagement, reducing strain on internal engine and transmission components.

The stored rotational energy in a flywheel mirrors this scenario: once you engage/disengage gears again, this stored energy smooths out transitions so they aren’t as sudden, avoiding unhealthy slippage.

In terms of construction, flywheels, similar to cylinders and coil springs, can be weight-differentiated for different applications – a lighter flywheel will provide faster revs but might impact durability and clutch life expectancy through increased wear. Conversely, heavier flywheels can give a smoother feel in lower RPM ranges and better low-end acceleration, but at the cost of slower revs overall.

Another factor worth mentioning is understanding the various materials used for components like flywheels, cylinders, and coil springs and their advantages/disadvantages. Stock flywheels are often made from cast iron, which tends to be durable but heavy. Aftermarket performance parts, on the other hand, may use lightweight materials like aluminum alloys to reduce weight and improve engine response.

Some drivers may wonder if the cost of upgrading their flywheel, clutch fork, or entire clutch kit outweighs the benefits. There are pros and cons to replacing any part of your vehicle’s clutch system, including replacing your existing OEM flywheel with an aftermarket performance-flywheel.

On the one hand, high performance flywheels may offer higher benefits such as faster engine revving times and lower inertia for smoother gear changes, as well as mechanically stronger materials that last longer than OEM cast iron. Moreover, optimizing the clutch fork can improve the suspension and steering quality, enhancing the driving experience.

On the other hand, these aftermarket parts can also pose potential reliability problems when paired with a weaker or unprepared clutch kit.

It can also be argued that a subtle enough improvement in flywheel performance, suspension, and steering may not justify the cost and time investment required for aftermarket installation. With an understanding of the flywheel’s and clutch fork’s roles in clutch system operation, we will next explore the process of engaging and disengaging your car’s clutch system.

The process of engaging the car clutch is simple in theory, but it requires coordination between different parts of the car to work effectively. When you press down on the clutch pedal, you are essentially separating the engine from the wheels. This allows you to shift gears without causing damage to your transmission system or your vehicle’s suspension and steering mechanisms.

Engaging the Car Clutch: How It Works

Imagine a bicycle with multiple gears. By pedaling backward and releasing pressure, you can easily change gears. The bike will not move without pedal pressure. The mechanism for shifting gears in a car works similarly because pressing down on the clutch pedal disengages the engine from the wheel and prevents it from sending any force to the transmission system, suspension, or steering mechanisms.

The role of friction between the clutch plate and flywheel is crucial during this process. When you release your foot from the clutch pedal, a spring pushes on a pressure plate, which then compresses a series of springs onto a friction disc. This causes the disc and flywheel to become connected again through the clutch fork, allowing energy to be transferred from the engine to the wheels, thereby affecting the vehicle’s suspension and steering capabilities.

However, understanding how friction plays a role in this process requires that we explore more about how the clutch system works in conjunction with pressure.

When you depress the clutch pedal, you release pressure that separates two surfaces – in this case, the flywheel and clutch plate. To fully comprehend how these two components interact, we must first understand their roles in engaging and disengaging power transfer, as well as how they influence the suspension and steering of the vehicle.

The Role of Friction and Pressure

Think of placing your hand on a table surface or desk. Without applying any force, your hand doesn’t stick or move anywhere; there’s no friction yet because things are just resting there passively. But when steering or manipulating the clutch fork and hence the suspension, if you apply some pressure or force, your hand can now move across the surface and feel the resistance as it moves.

Think of placing your hand on a table surface or desk. Without applying any force, your hand doesn’t stick or move anywhere; there’s no friction yet because things are just resting there passively. But if you apply some pressure or force, your hand can now move across the surface and feel the resistance as it moves.

Similarly, when you press down on the clutch pedal, you’re applying force, which causes the pressure plate to push friction discs towards the flywheel. This creates a grip that allows power transfer once the pedal is released. Maintaining your clutch system in good condition will be largely based on taking care of its component parts, such as friction discs and flywheels.

A skilled mechanic who is familiar with assessing the state of these parts should inspect them because they naturally wear out over time from use. Replacing worn-out parts promptly will help prevent damage to other systems while maintaining optimal performance.

There are also arguments suggesting that high-performance clutches with heavier pressure plates cause excessive wear and tear on flywheels, leading to potential failures. While true in many cases, this issue doesn’t apply if you’re using aftermarket components built for heavy-duty driving or racing events.

The relationship between pressure and friction is closely tied to how well your car’s clutch functions. With an understanding of how these work together, we can now begin exploring what happens when you disengage the clutch system – which will be covered in detail.

Disengaging the Car Clutch: What Happens?

Disengaging the car clutch is a crucial step in ensuring that your vehicle runs smoothly. This process involves separating the engine from the transmission, allowing you to shift gears and control acceleration. Once you press down on the clutch pedal, the clutch disc disengages from the flywheel, stopping power from transferring to the wheels.

To give you an idea of how this works, think of a bike without brakes. When you pedal forward, the chain rotates and drives the rear wheel forward. If you want to slow down or stop, you have to backpedal or apply pressure to the brake pads on the rim. However, if there were a separate mechanism that could stop power transfer between your pedals and the rear wheel (like a clutch on a car), you would be able to change gears effortlessly and control your speed much better.

In simpler terms, when you disengage a car’s clutch, you are disconnecting the engine from the transmission so that it can continue running without having an impact on other moving parts in your car. If this separation doesn’t happen smoothly or efficiently enough, you may experience problems like stalling or grinding noises.

However, some people might argue that pressing down on the clutch pedal is just an unnecessary added step that complicates driving.

While it’s true that automatic transmissions don’t require drivers to manually disengage their clutches, they do come with their own set of limitations and complications, not to mention higher upfront costs than manual vehicles. Ultimately, whether or not you find manual shifting inconvenient is up to personal preference, but understanding how your car’s clutch system works can help make any driving experience smoother and more efficient.

The Release Mechanism Explained

Now that we know what happens when we disengage a car’s clutch, let’s talk about how it happens. When you press down on the clutch pedal with your foot, your input is transferred to the clutch release fork, which then pushes the clutch release bearing against the diaphragm spring.

The pressure plate is a mechanism that constantly presses a group of circular metal discs together under tension to form the diaphragm spring. Think of this like squeezing a water balloon from both sides; when you apply pressure evenly all around, the balloon stays in one piece. But if you focus too much pressure on one side, that side will bulge out while the rest of the balloon stays mostly intact.

In the case of a clutch system, the diaphragm spring applies even pressure around the circumference of the clutch disc, allowing it to engage and disengage smoothly. However, just like any mechanical component, these parts can wear out or break over time from everyday use. Clutch cables might stretch or snap, or friction plates could become worn down and lose their grip.

If you notice any unusual grinding or slipping sounds when shifting gears or difficulty switching between gears at all, it may be due to problems with one or more components of your vehicle’s clutch system.

Some drivers may wonder why there are so many different parts involved in disengaging a clutch—wouldn’t it be simpler if there was only one mechanism involved? Having multiple components, on the other hand, allows for greater precision and control over how power is transferred between different parts of your vehicle’s engine and transmission.

For example, by controlling how much tension is applied to the pressure plate or adjusting the shape and material of the friction pads on the clutch disc, engineers can design high-performance clutches that can handle greater loads and speeds without sacrificing reliability.

Common Clutch Problems and Maintenance Tips

Clutches are one of the most crucial components of any vehicle’s transmission system. They play a vital role in providing smooth shifting and efficient acceleration, making it essential for car owners to ensure that their clutches are operating correctly. However, even with proper maintenance, clutches can experience problems that require immediate attention.

We will discuss the most common clutch issues drivers face and provide clutch maintenance tips in this section. The first and most common issue that drivers face is worn-out friction material on the clutch plate.

Over time, the friction material wears down or becomes contaminated with oil or other fluids, which reduces its frictional grip on the flywheel. As a result, the clutch may start slipping or fail to transmit power smoothly from the engine to the gearbox. Drivers may notice symptoms such as difficulty accelerating or changing gears, an unusual burning smell emanating from under the hood, or a loss of power while driving uphill.

To prevent these issues, drivers should ensure that they replace their clutch plates at regular intervals or when signs of wear become evident. Additionally, avoid riding the clutch pedal too often or operating your vehicle with unnecessary weight in tow, as both activities can accelerate wear and tear on your clutch system.

Another problem that drivers face is sticking clutch pedals. Several factors can cause sticking pedals, including broken or stretched cables, damaged hydraulic lines, or worn-out bearings in the release mechanism.

Sticking pedals can be dangerous as they can prevent drivers from disengaging their engines from gear, leading to stalls and even crashes. To fix this issue, drivers should perform regular check-ups on their release mechanisms and adjust accordingly when necessary.

Lubricating moving parts and replacing damaged components early will go a long way toward preventing this type of problem. Lastly, another significant problem facing drivers is clutch judder. Clutch judder is a situation where the clutch does not engage or disengage smoothly. Instead, it causes jerky movements in the car that can be uncomfortable to experience.

Some common culprits for clutch judder include oil contamination of the flywheel and pressure plate surfaces or misaligned transmission gears.

To deal with this problem, some drivers solve it by performing severe methods such as stripping down the clutch system completely. However, this method can lead to premature wear and tear on your vehicle’s transmission parts and increase costs. To prevent this, drivers should contact professional mechanics for expert advice or seek other less invasive solutions.

Imagine the car’s drive train like a bicycle chain—a worn-down chain can lead to sloppy gear shifts or slips that prevent efficient use of power. Similarly, ignoring regular maintenance requirements on your clutch system can lead to unnecessary wear and tear, premature failure, and increased repair costs.

In summary, taking good care of your car’s clutch system is one of the most critical aspects of vehicle maintenance, as it affects drivability and safety. With regular check-ups and preventative measures such as scheduled replacements and fluid changes, you can avoid these common issues and ensure that your car runs smoothly every day.

Enhance Your Driving Experience With Expert Clutch Repair in Waltham, MA

A vehicle’s clutch, a critical component of the manual transmission system, enables seamless gear shifting and smooth acceleration. Over time, wear and tear can take a toll on this intricate mechanism, resulting in decreased performance and potential failure.

However, fear not, for the experienced mechanics at Riverside Transmissions possess the knowledge and expertise required to diagnose and rectify any clutch-related issue. Utilizing state-of-the-art diagnostic tools, our certified professionals meticulously inspect the clutch system, pinpointing the root cause of the problem.

From adjusting the clutch pedal and replacing worn-out components to addressing clutch slippage and resolving hydraulic leaks, our team leaves no stone unturned when it comes to restoring the optimal performance of your clutch system.

Give us a call today for more information and to book an appointment!